Melting has equipped with INDUCTOTHERM TRI TRACK with latest technology of power control.

Melting

- 1000Kg- Inductotherm Induction furnace 3 No’s TRI TRACK.

- Connected Power – 2250 KVA.

- Spectro Result feedback unit with jumbo display.

- Immertion pyrometer and cyclopes for checking of molten metal temperature.

- Melting Rate – 3.0MT per Hr.

- Annual Production capacity – 12,000MT.

- Wet scrubber for pollution control.

Moulding Line 1

Moulding has equipped with Disa match 20 x 24 high pressure with horizontal parting line machine. Moulds produced in this line has exceptional dimensional accuracy and superior surface finish.

Specification

- Mould cake size – 610 x 508 x 150- 200 mm

- Mismatch – 0.15mm Max

- Speed 120 molds/hour without core

- Speed 100 molds/hour with core

Moulding Line 2

Fast Loop Molding line & Hand Mold

Specification

- Process :RESIN SAND PROCESS

- Sand Mix tons : 20MT

- Max Cake Size 1350 X 1050 X 450/450

- Production Capacity : 150 MT/Month (1800 MT/annum)

- Production Rate -5-7 Moulds/Hr

- Product Weight ≥30 Kg to ≤300 kg for Fast loop line

- Product Weight Max 1MT for Hand Mold

- Auto-matic Mould Handling Unit

- Molding Track: Dual Track

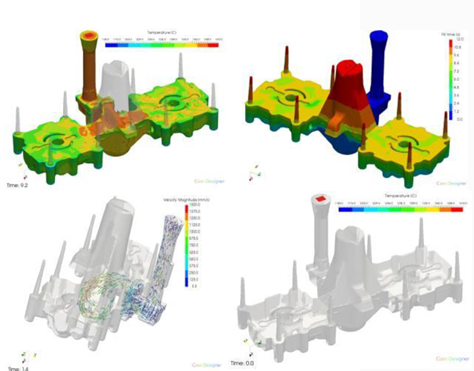

Simulation and 3D Modelling

- Solid works for 3D Modeling

- Cast design for Casting Simulation

- Metal flow and filling

- Solidification

- Air Entrapment

- Result Summary

Sand Plant

Sand Plant

In order to optimize the working of the Automatic High-Pressure Moulding Line, the Company has also installed a state-of-the-art Automatic Sand Plant which incorporates:

- Disa SAM 3-40mixer with SMC (Sand Multi Control ).

- 30 Ton/hour sand plant with complete dust collection system.

Specification

- Intensive sand – 1.0MT per Batch

- Sand Storage – 180 MT

- Sand plant operated by SMC control

- Sandman software for online Sand Control.

- Sand cooler-40MT-Wesman Make

Core Shop

| Machine | Specification |

| Cold Box Core shooter – GS –Horizontal shooting | Shooting Capacity – 20 Kgs. Mode of operation – Fully Automated |

| Cold Box Core shooter – GS –Horizontal and vertical shooting | Shooting Capacity – 20 Kgs. Mode of operation – Fully Automated |

| Cold Box Core shooter – GS –Vertical shooting | Shooting Capacity – 10 Kgs. Mode of operation – Fully Automated . |

| Cold Box Core shooter – GS –Vertical shooting | Shooting Capacity – 5 Kgs. Mode of operation – Fully Automated . |

| Shell Core shooter – Susha - Vertical shooting | Shooting Capacity – 5 Kgs. Mode of operation – Semi- Automated . |

| Core oven | 500 Kg/ Batch Heating Temp –up to 240 Deg |

Fettling And Dispatch

- Shot blasting –Hanging type – 500Kg/Batch DISA

- Shot blasting –Hanging type – 500Kg/Batch GOSTOL

- Thumb Blasting – 250 kg/Batch

- Nozzle blasting

- Installed Capacity – 800MT /Month